In the field of high-precision manufacturing, one of the biggest challenges is maintaining stability and support on slender or long or flexible parts. This is the point where the hydraulic steady rests are required. These essential machine tool accessories provide solid support to workpieces while turning, grinding or other machining tasks. Optimized for performance, stationary hydraulic rests provide vibration-free performance, improved surface finish, and higher machining accuracy. Hydraulic Steady Rests

If you're using CNC Lathes, or more traditional machines, adding a hydraulic steady stop can dramatically increase production and quality of the workpiece.

What is an Hydraulic Steady Rest?

A hydraulic steady rest is an mechanical apparatus used in conjunction with lathes or grinding machines to hold a workpiece that is rotating at any of the points between the spindle and tailstock. It uses an hydraulic pressurization to control and move arm supports that connect to the surface of the workpiece, providing solid and stable clamping force throughout the process of machining.

They usually come with at least three arms of support (sometimes greater), each equipped with pads or rollers that ensure a consistent dispersion of clamping pressure while not damaging the workpiece.

The most important components of a Hydraulic Steady Rest

Understanding the structure helps to recognize the effectiveness in these gadgets:

Support Arms generally three that are hydraulically controlled to align the workpiece.

Hydraulic Cylinder controls the motion of arms making sure that they are synchronized and have smooth operation.

Pads or Rollers Contact points are able to grip the workpiece lightly yet firmly.

Mounting Base This base ensures secure attachment with the machine bed turret.

Feedback Sensors (optional): Some advanced models incorporate sensors for automated clamping and position verification.

Do Hydraulic Steady Rests Work

If a piece of equipment is positioned onto a lathe for the purpose of machining, it tends to be able to deflect or shake, particularly if it is long or has a tiny diameter. This deflection leads to inaccuracies and poor finish on the surface as well as the risk of damaging tools. A hydraulic steady rest functions in the following manner:

Positioning: The steady rest is located at the proper position on lathe bed.

Hydraulic Actuation The hydraulic fluid pressure shifts the support arms towards the workpiece.

Centering: Arms press the workpiece evenly, centered it, thereby reducing runout.

Support during Machining The workpiece turns, the fixed rest maintains constant pressure and alignment, minimizing vibration and deflection.

This mechanism allows users to machine larger parts at faster speed without sacrificing precision.

Benefits of Using Hydraulic Steady Rests

1. Improved Machining Accuracy

By removing vibrations and deflection by using steady rests, the tool stays on a stable cutting path. This improves the precision.

2. Enhanced Surface Finish

More movement and less chatter means more polished surfaces. This is particularly crucial in applications that require high tolerance, such as aerospace or medical equipment.

3. Increased Tool Life

In addition, reducing vibration reduces tool wear and tear, extending the lifespan of costly cutting tools.

4. Automation-Friendly

Hydraulic steady rests are easily integrated into CNC systems, allowing faster setup and reduced involvement by hand.

5. Safe Operation

A firm clamping of the workpiece reduces the chance of accidents or slippage and protects both the machine and the user.

The applications of Hydraulic Steady Rests

Hydraulic steady rests are utilized in a variety of industries:

Automotive: Supporting long camshafts, crankshafts, or axles during machining.

Aerospace: High-precision machining of landing gear or structural components.

Oil & Gas: Turning pipes, long shafts.

General Engineering: Any task that requires vibration-free and precise turning of slender components.

Types of Hydraulic Steady Rests

Hydraulic steady rests are categorized based on mounting and functionality:

1. Fixed Steady Rests

They are positioned in a fixed location on the lathe bed. They are ideal for repetitive work and regular part sizes.

2. Traveling Steady Rests

They are mounted on the carriage or cross-slide, they slide alongside the cutting tool. Ideal when the tool as well as support require to be in the same place during operation.

3. Turret Mounted Steady Rests

Typically, they are utilized in CNC lathes. They sit in the turret and could be automatically positioned as part of an CNC program.

Some Things to Consider before Choosing a Steady Rest

1. Workpiece Dimensions

Make sure the rest is stable and supports the entire diameter of your common workpieces. Most rests come with a minimum and maximum clamping diameter.

2. Machine Compatibility

Verify compatibility with your CNC or manual lathe, including mounting interfaces and power supply availability for hydraulics.

3. Clamping Force

Insufficient force can cause deformation to fragile parts. Too little won't offer enough support. Opt to have an adjustable force control when available.

4. Feedback Options

To automate operations, sensors-equipped stationary rests can provide position feedback and security interlocks.

5. Repair and Quality

Choose models with easy-access service points, hydraulic systems that are sealed and sturdy materials to endure the harsh industrial conditions.

Installation and Maintenance Tips for Maintenance and Installation

Alignment is important The misalignment between the steady rest and the spindle may damage the workpiece or the machine.

Hydraulic Lines Check Check hoses regularly along with connections to look for leaks, or obstructions.

Lubrication ensure that moving components including rollers are properly lubricated.

Cleaning: Chips and debris must be removed frequently to avoid jamming or unbalanced clamping.

Routine Calibration The calibration process is a time-based one. the steady rest may drift--periodic recalibration ensures precision.

Challenges and Limitations

Although extremely useful and useful, the hydraulic steady rests not without pitfalls:

Start Cost: More expensive than regular steady rests.

Complexity: Requires hydraulic setup. It may also require programming integration within CNC machines.

Size Limitations Each model can support only a particular diameter range which means that there are multiple models to accommodate varied part sizes.

However advantages, the performance gains generally surpass the drawbacks for the majority of industrial users.

Conclusion

Hydraulic steady supports are crucial equipment in the modern machining environment where efficiency, precision, and automation are essential. By offering a rigid support structure and making sure that vibrations are minimized, they increase the performance of tools, workpieces and worker safety. In aerospace, automotive, or general engineering applications investing in the proper hydraulic steady rest will transform the way you machine, providing precision, accuracy, and confidence with every cut.

As industries continue to demand higher productivity and more precision The hydraulic steady rests not merely an option anymore. They are essential components in precision manufacturing.

Molly Ringwald Then & Now!

Molly Ringwald Then & Now! Charlie Korsmo Then & Now!

Charlie Korsmo Then & Now! Jenna Von Oy Then & Now!

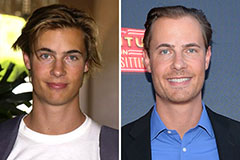

Jenna Von Oy Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Earvin Johnson III Then & Now!

Earvin Johnson III Then & Now!